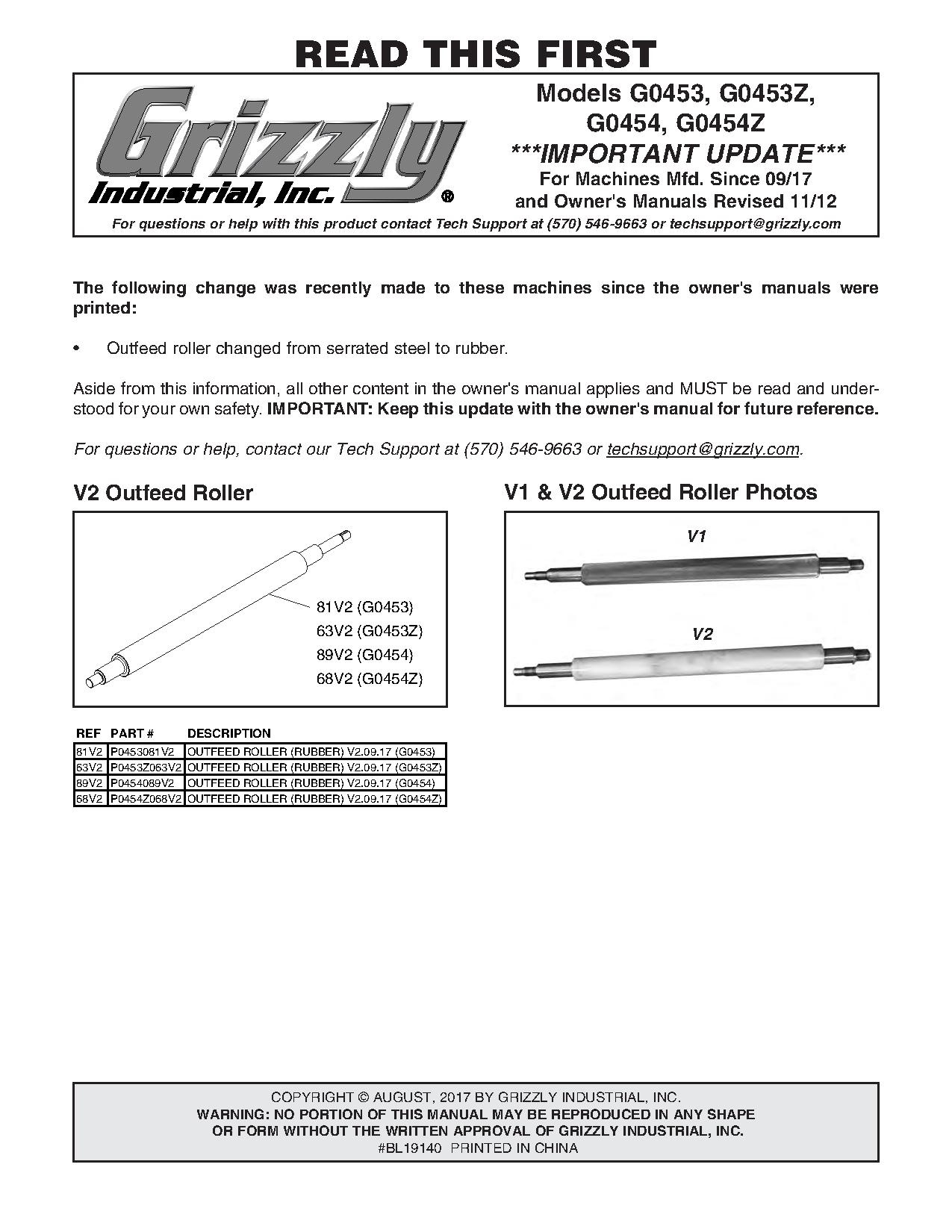

Grizzly 20" Planer

From Pumping Station One

|

Authorization Course Info |

|

Woodshop Basic Schedule Frequency: Multiple times per week, scheduled through Canvas. May be booked up to a month out. Discord Channel: #woodshop-general Step 1: Complete the Woodshop Tool Canvas course Step 2: Use Canvas to schedule with the next available in-person auth Step 3: Attend and complete the in-person auth Required Materials: Required: safety goggles, closed toed shoes, no loose clothing. Optional: mask, ear protection Tools covered: You must be logged in to perform this action or view this special page. Edit this auth Copy and paste this into the tool's wiki page after the Template:EquipmentPage template. {{:Authorizations/Woodshop Basic}} Auth info last updated by Makelemonade on January 08, 2026. |

Guidelines for proper use

This tool requires authorization for use.

Only wood should be run through the planer. No pressure treated wood, and no wood products. This means no plywood, MDF (Medium Density Fiberboard), OSB (Oriented Strand Board). The dust produced from these is toxic.

- Always check your wood for nails or staples. Something as small as the staple at the end of a 1x1 can ruin the blades. If you're not sure, check the entire piece with the metal detector sitting on the table saw.

- Always measure the thickness of your work and set the initial and working blade height to remove only small amounts of material per pass. You will damage the blades if you manage to dig the machine out on your work.

- If the machine is making a strange noise when you use it, there is a problem, and you should ask for help.

- If the blades are dull or damaged, contact the area host immediately.

- If you break something, or damage the tool, contact the area host immediately. Don't let others do more damage or hurt themselves by using a broken tool.

- Always make sure that the dust collection bag isn't too full and is passing air freely.

- Always vacuum the machine, cutting area, and the table around the machine when you are done.

Checklist

*NEED TO CREATE AND Add maintenance checklist document.*

Hour meter is installed.

We're going to try to follow the preventative maintenance schedule from Grizzly which is as follows.

Grizzly Defined Maintenance

Ongoing Cleaning and Protection:

- Vacuum excess wood chips and sawdust from the outside of the machine, inside the cabinet, and off the motor. Protect the unpainted cast iron surfaces on the table by wiping the table clean after every use—this ensures moisture from wood dust does not remain on bare metal surfaces.

- Keep tables rust-free with regular applications of products like G96® Gun Treatment, SLIPIT®, or Boeshield® T-9 from Grizzly.

Every 8 Hours of Operation:

- Clean the machine and protect unpainted cast iron.

- Lubricate the feed rollers bushings (Page 29).

- Tighten loose mounting bolts.

- Check/rotate/replace damaged or worn inserts (Page 34).

- Check/repair/replace worn or damaged wires.

- Resolve any other unsafe condition.

Every 40 Hours of Operation:

- Lubricate the table columns and leadscrews (Page 29).

- Clean/vacuum the dust buildup from inside the cabinet and off motor.

Every 160 Hours of Operation:

- Check/tension/replace the V-belts (Page 35).

- Lubricate the table height worm gear (Page 29).

- Lubricate the table height chain and sprockets (Page 30).

- Lubricate the drive chain and sprockets (Page 30).

Yearly:

- Change the gearbox oil (Page 30).

External Links

- Manufacturer Page

- Owner's Manual

- Maintenance Doc

Reference Material

Link to Grizzly Product Page for Additional Information

Maintenance Logs

- 1/31/25 - Nick, Locke, Pat

- Unloaded and setup machine

- Wings leveled, gearbox oil topped off, bed rollers checked

- Modifications made

- junction box on lower front left for ecogate current meter. switched to barrel jack for ecogate low voltage connector.

- hour meter installed on back left.

- broke off a tack welded nut on the front left corner for the adjustable foot. to be fixed later. machine is up on 4x4s for now. in service.

- Unloaded and setup machine